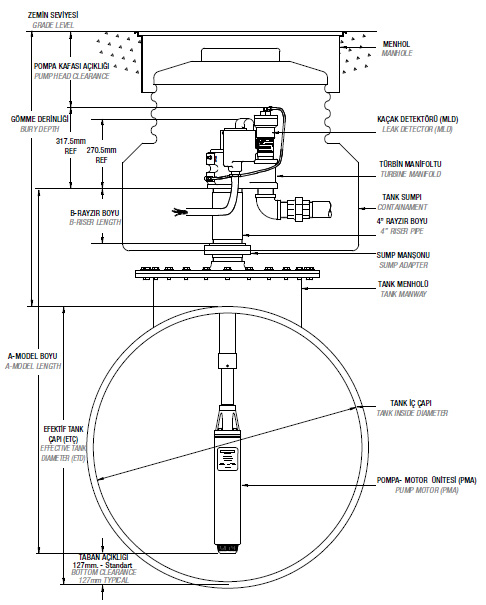

Submersible Turbine Pumps

Since the mid-1950s, Franklin Electric, the parent company of Franklin Fueling

Systems, has been involved in the design and manufacture of submersible motors for

use in pumping liquids. Building on this extensive history, FFS has contributed innovative

product designs for submersible pumps into the twenty-first century. Marketers

concerned about fuelling times, efficiency, serviceability, reliability and overall quality find

it an easy choice to specify FE Petro products from FFS.

Consider these unique FE Petro product features to improve the profitability of your

retail operations:

ADVANTAGES

Faster Fuelling Times

With innovations like MagShellTM, FE Petro products set the standard for submersible

pump performance.

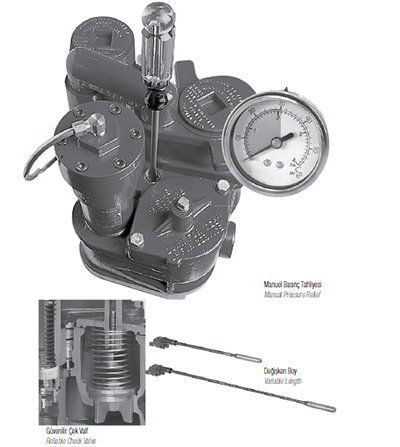

Active Air Eliminator

FE Petro products come standard with active air elimination, which eliminates air

through the highest point in the pump head at all times when the pump is running,

assuring air does not pass into discharge piping.

Safety and Ease of Maintenance

FE Petro STPs include a contractor electrical disconnect, which requires loosening

only one bolt, allowing motor wiring to be disconnected without venting the dangerous

tank vapours into the sump when servicing FE Petro submersible products.

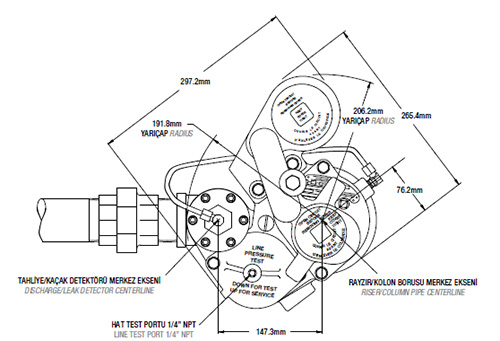

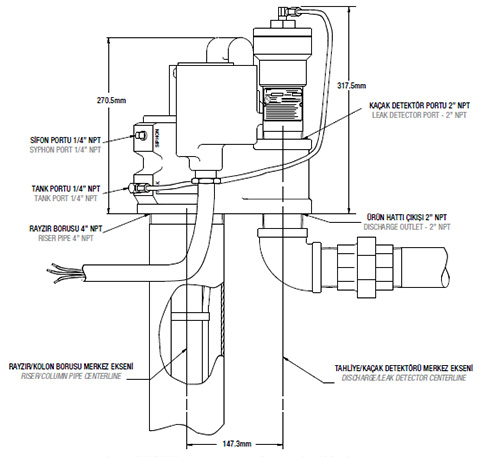

Simple Servicing

If ever required, the pump can be easily removed from the tank by unthreading three

bolts. There is no need to disconnect the syphon system or to remove the leak detector

from the system to service the STP.