Franklin Products

- Submersible Turbine Pumps

- Intelligent Submersible Turbine Pumps

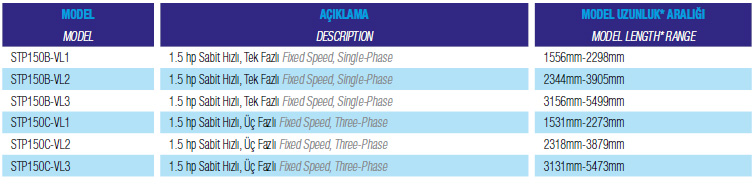

- 1½ hp Fixed Speed Submersible Turbine Pump Specifications

- 2 hp Fixed Speed Submersible Turbine Pumps

- Pump Motor Assemblies For Def/Adblue

- Guardian Series Fixed Speed Pump For Controller

- Fuel Management Systems

- Fuel Management Systems EVO SERIES

- EVO Line Leak Detection

- Digital Inventory & Leak Detection Probes

- Sensors

- Pipe Equipment

- UPP Primary Pipework

- UPP Secondary Contained Pipework

- Other Products

- DEF / Adblue® Shear Valves

- Sealing Dip Cap

- 63x50mm 1.5” Pipe System

- 75x63mm 2” Pipe System

- 125x110mm 4” Secondary Contained Pipe System - Gemini

- 230V & 110V EF1 Welder

FRANKLIN

1½ hp Fixed Speed Submersible Turbine Pump Specifications

Market players concerned about refueling times, efficiency, ease of service, reliability, and overall quality see specifying FE PETRO brand submersible turbine pumps (STPs) as an easy choice. An STP must be reliable, safe, and deliver performance. That’s why thousands of station owners worldwide have trusted FE PETRO STPs and the Franklin Electric motors that power them for over 30 years to keep their businesses running. Supported by best-in-class flow rates and a long track record of reliability, FE PETRO STPs get the job done flawlessly, delivering fuel to customers every day without interruption.

STANDARD FEATURES

› 1½ hp fixed speed models are available in variable and fixed length options.

› Check valve: 70mm diameter fluorocarbon seal constructed on cast aluminium body and steel backing washer.

› Pressure relief valve: available in four pressure relief settings, integral to check valve. Standard model relieves at 2.76 bar and resets above 2.41 bar.

› Syphon: venturi-type syphon primer supplied with every submersible. Syphon check valve and secondary syphon sold separately.

› Air eliminator: every submersible includes a tank return path with one-way check valve to provide active air elimination.

› Electrical disconnect: electrical yoke for positive contractor disconnect during service.

› Please contact us for fixed speed 2HP models

POWER REQUIREMENTS

150B models require single-phase, 200-250 VAC, 50 Hz incoming power.

• 150B models incorporate a starting and running capacitor, with internal bleed resistor, rated 440 Volt,15 microfarad.

• STP-SCI single-phase smart controllers and STP-CBBS single-phase control boxes are available for 150B control.

• 150C models require three-phase, 380--415 V, 50 Hz incoming power.

• STP-SCIIIC three-phase smart controllers available for 200C control.

PUMP MOTOR

1½ hp fixed speed, 2875 rpm, multi-stage centrifugal type pump motor with integral, automatic, thermal overload protection.

LIQUID COMPATIBILITY

Max. liquid viscosity: 70 SSU at 60°F (15°C).

• Standard models are listed for fuel mixtures containing up to 10% ethanol with gasoline, and 20% MTBE, 20% ETBE or 17% TAME with gasoline.

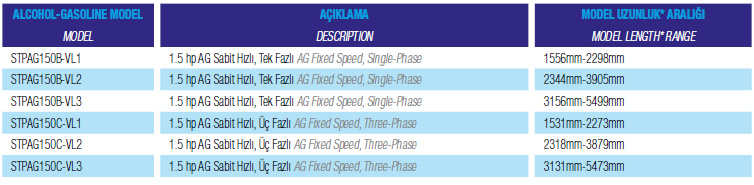

• STPAG models are compatible for fuel mixtures containing diesel fuel with up to 20% biodiesel, 100% biodiesel, up to 85% ethanol with gasoline, and 20% MTBE, 20% ETBE or 17% TAME with gasoline.

• 1½ hp fixed speed models can also be used with diesel fuels, fuel oils, kerosene, Avgas and jet fuels in a non-gelled pourable state.

• All wetted elastomers are made of a high grade, fluorocarbon compound.

APPROVALS

• Consult factory for applicable approvals.

QUALITY CERTIFICATION

Franklin Fueling Systems is an ISO 9001 Certified Manufacturer.

1½ hp Fixed Speed Submersible Turbine Pump Specifications

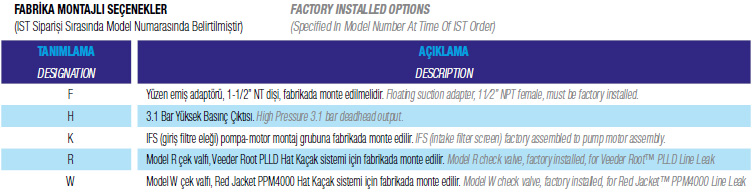

1 ½ HP FIXED SPEED SUBMERSIBLE TURBINE PUMP MODEL DESIGNATION SYSTEM

A typical turbine model designation has up to five components to define the pump

being supplied as follows:

STP XXXXX Y - A - B

STP = Basic Model Designation

XXXXX = Factory Installed Options

STP model designations may include one or more of the following characters in

alphabetical order:

AG = Alcohol-gasoline compatible (up to 85% ethanol, up to 20% biodiesel, or 100%

biodiesel) Note: Standard models up to 10% ethanol capable.

F = Floating suction adapter (11⁄2” NPT female adapter)

H = High pressure (3.1 bar deadhead (no flow output))

K = Intake filter screen (IFS, factory installed to PMA)

*R = Model R check valve (1.65 bar relief/1.52 bar reset for PLLD)

*W = Model W check valve (1.10 bar relief/ 0.89 bar reset for PPM4000)

*Note: If not otherwise specified, all STP models supplied with standard model check

valve (2.76 bar relief/2.41 bar reset for MLD, TS-LS300 and TS-LS500).

Y = Pump Motor Horsepower Rating **

150B = 11⁄2 hp fixed speed, 50 Hz, 1-phase

150C = 11⁄2 hp fixed speed, 50 Hz, 3-phase

A = Model Length

VL1 = Variable length range #1.

VL2 = Variable length range #2.

VL3 = Variable length range #3.

Note: VL2 models fit 94% of all known installations.

B = Riser Pipe Length

Riser pipe length is expressed as two numeric characters that indicate the total length

of the riser in inches. Riser pipes are available from 178mm to 1753mm in 25.4mm

increments (additional charge for risers 787mm or longer).

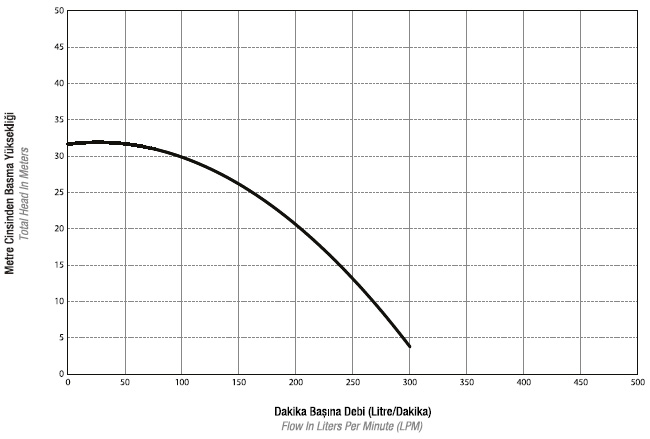

1½ hp Fixed Speed Turbine Performance Chart (STP150B)

Note: Performance based on pumping solvent (0.78 specific gravity). Pressure is taken

at the manifold discharge outlet. Fixed Speed 1.5 HP was powered by Single-Phase, 50

Hz, 250 Volt incoming supply.

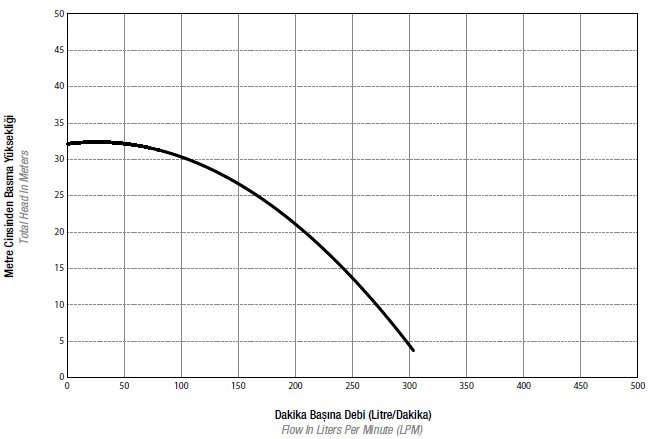

1½ hp Fixed Speed Turbine Performance Chart (STP150C)

Note: Performance based on pumping solvent (0.78 specific gravity). Pressure is taken

at the manifold discharge outlet. Fixed Speed 1.50 HP was powered by Three-Phase, 50

Hz, 415 Volt incoming supply

1½ HP Fixed Speed Submersible Turbine Pumps

1. STP models are compatible with fuel mixtures containing up to 10% ethanol with gasoline, diesel fuel, and 20% MTBE, 20% ETBE or 17% TAME with gasoline. STPAG models are

compatible with fuel mixtures containing diesel fuel with up to 20% biodiesel, 100% biodiesel, up to 85% ethanol with gasoline, and 20% MTBE, 20% ETBE or 17% TAME with gasoline.

2. All models are supplied with a standard check valve unless factory option “R” or “W” is specified.

3. 4” riser pipe, if supplied locally, must be 41⁄2” OD by 3/16” WT tubing.

4. 150B models require single-phase, 200-250 VAC, 50 Hz incoming power. 150C models require three-phase,

380-415 VAC, 50Hz incoming power.

5. For riser pipe lengths 787mm to 1753mm, additional charge applies.

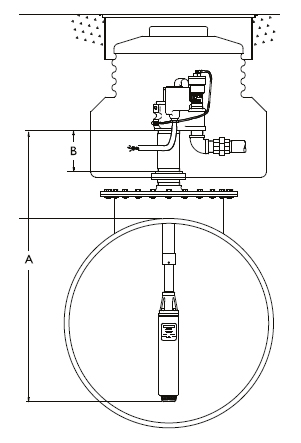

*Model length (A) defined as the dimension from turbine manifold bottom to pump motor inlet.