Mechanical Line Leak Detector

For use with 4” STPs, the MLD product line is precision built, with unique construction

features that provide busy stations with maximum flow rates and long service life.

The MLD is offered in two models to match your exact application, ensuring accurate,

nuisance-free operation critical to profitable station operation.

SPECIFICATIONS:

Two models: STP-MLD (blue) for gasoline and STP-MLD-D (tan) for diesel.

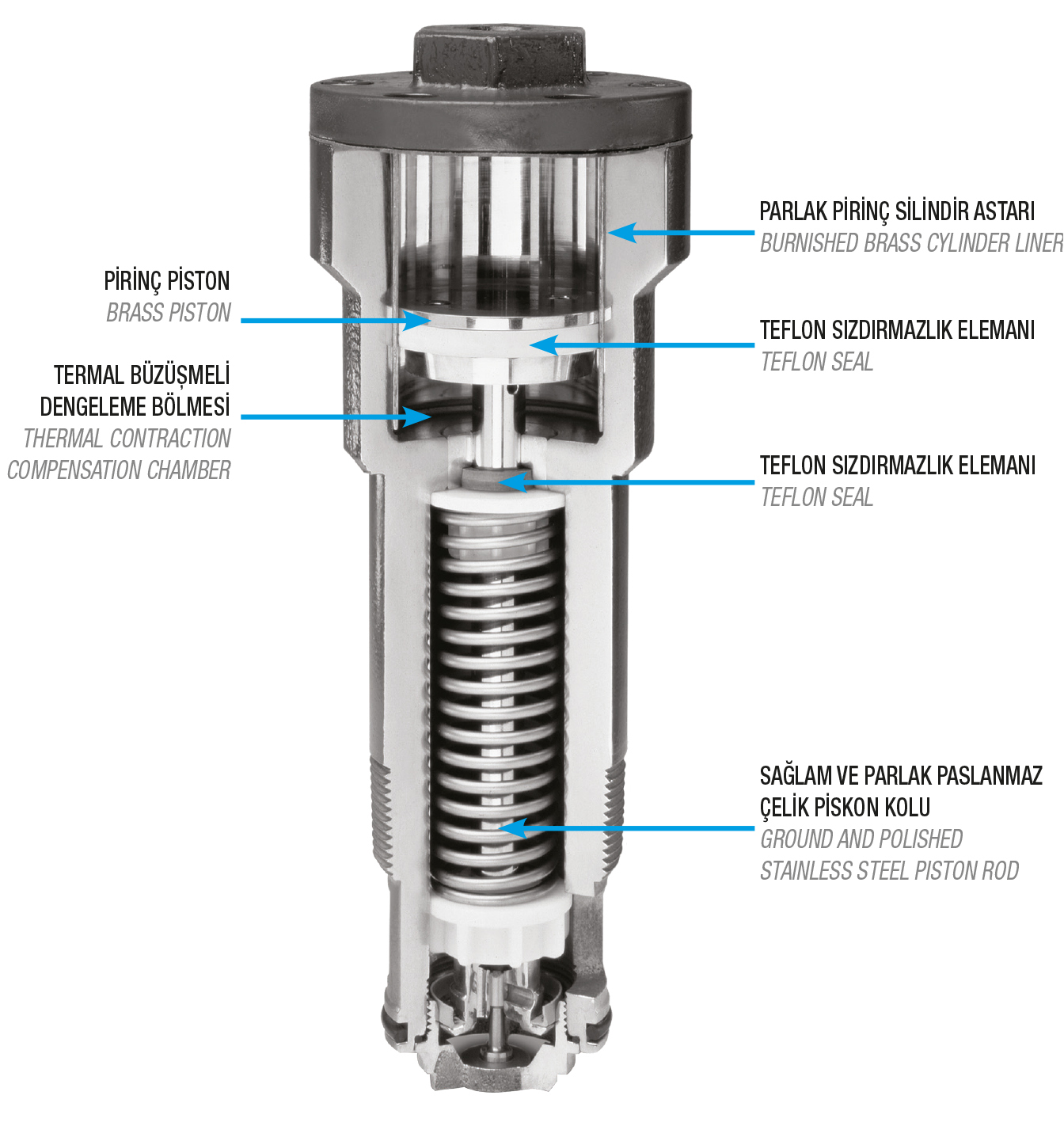

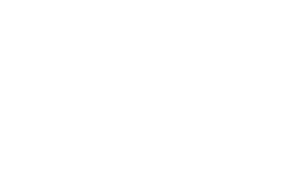

• Solid brass piston has 41.3mm of travel to move the leak detection poppet fully out of

the flow, offering minimum flow restriction and maximum flow rates.

• Burnished brass cylinder liner and polished stainless steel piston rod ensure smooth

operation and long life from the Teflon seal.

• Thermal compensation chamber of 94.2 cubic centimeters helps minimise thermal

contraction nuisance tripping.

Liquid Compatibility

Max. liquid viscosity: 70 SSU at 60°F (15°C).

• STP-MLD models are compatible with fuel mixtures containing up to 10% ethanol with

gasoline, and 20% MTBE, 20% ETBE or 17% TAME with gasoline, as well as diesel fuels,

fuel oils, kerosene, Avgas and jet fuels.

• STP-MLD-D models are listed for diesel fuels or kerosene only.

APPROVALS

Third party certified to comply with US EPA requirements 280.41 (B) and 280.44 (A) for

continuous monitoring of pressurised piping.

• Consult factory for other applicable approvals.

QUALITY CERTIFICATION

Franklin Fueling Systems is an ISO 9001 Certified Manufacturer.

ADVANTAGES

All models are capable of detecting line leaks equivalent

to 11.4 lph at 0.68 bar when installed properly with the

appropriate fuels. All models will signal detection of leaks

by restricting product delivery to less than 11.4 lpm and

taking more than 4 seconds to open.

• All models require 2 to 3 seconds to make a line test

when no line leaks exist and air is purged from piping

between the discharge of the MLD and the dispenser

solenoid.

• All models will remain in the “open” position during

product delivery to manifold, with discharge pressures as

low as 0.069 bar. All models will reset to “tripped” when

line pressure delay is below 0.207 bar with pump off.

• All models will detect leaks up to 3.04m above the MLD

installation point.