OPW

Above Ground Storage Tank Equipment

144TA AND 444TA LIQUID LEVEL TANK ALARM

OP.AST.444TA.0100 / OP.AST.144-TA 0100

› 444TA can be used for high or low liquid level sensing,

interstitial monitoring, and/or other signals in one to 4

separate tanks.

› 144TA is designed for single alarm for liquid level

sensing

› Provides a long service life with 10 year shelf life

lithium battery.

› Sounds a 90 decibel alarm at 1.2 meter away

› Red alarm light will flash during use for notification to

the user. Low battery light indicates when battery needs

replaced.

› Intrinsically Safe

› Temprature rating of -40 +48 degree celcius

› TGTA-0400 4” Tank combo fitting and 44TA-LLFS are

supplied additionally

301 SERIES EMERGENCY VENTS

OP.AST.301

› 301 Emergency Vent is designed to prevent an

above ground tank from becoming pver-pressurized by

providing high-capacity venting in the event of a fire or

blockage

› It is a weighted, mushroom-style vent. Cast iron lid is

forced up to relieve the presure and reseats by its own

weight once the pressure is relieved

› Supplied with 4”, 6”, 8” and 10” sizes and female NPT,

male NPT or flanged connections

› Options to have either 32 or 64 mbar pressure set

values

202 SERIES EMERGENCY VENTS

OP.AST.202

› 202 Emergency Vent is designed to prevent an

above ground tank from becoming pver-pressurized by

providing high-capacity venting in the event of a fire or

blockage

› When the ast builds pressure to 0.17 bars, the springloaded

lid opens full-bore and discharges vapors

› The lid remains open to indicate a problem until

manually reset.

› Supplied with 4”, 6”and 8” with female NPT thread

connection

199ASV ANTI-SIPHON VALVE

OP.AST.199.ASV.2200

› Helps preventing siphoning of an ast should a leak

occurs in the fuel supply line

› Helps protect piping and fittings from damage due

thermal expansion via its internal pressure relief valve.

Set to operate between 1.3 to 2.7 bar

› Temprature rating of -49 +29 degree celcius

› Supplied with 3/4”, 1”, 1.5” and 2” with female NPT

thread connection

821 SOLENOID VALVE

OP.AST.821

› Helps preventing siphoning of an ast should a leak

occurs in the fuel supply line

› Normally closed diaphragm valve opens when

energized to allow fuel to flow. It is a two-way valve

› Strainer with 100 mesh screen is recommended at

the inlet.

› Supplied with 3/4”, 1”, 1.5” and 2” with female NPT

thread connection

21BV FULL PORT TWO-WAY BALL VALVE

OP.AST.21BV

› Used throughout fueling systems where a shut-off point

is desirable to isolate a section of the piping system

› Full-port, forged brass body features a manual openclose

arm

› Pressure rated to 41 bar.

› Supplied with 1/2”, 3/4”, 1”, 1.5”,2” and 3” thread

connection

178S SERIES EXTERNAL SHUT-OFF VALVE

OP.AST.178.S.6130

› Installed in-line on fuel supply piping, shut-offs product

flow in the event of a fire

› The fusible link melts at 71 degree celcius in the vent

of a fire and spring-actuated poppet shuts off the flow.

› Rated at normal pressure limit of 8.6 bar and has a

body design to allow full flow rate

› Temprature limit is 107 degree celcius.

› Supplied with 2” with female NPT thread connection

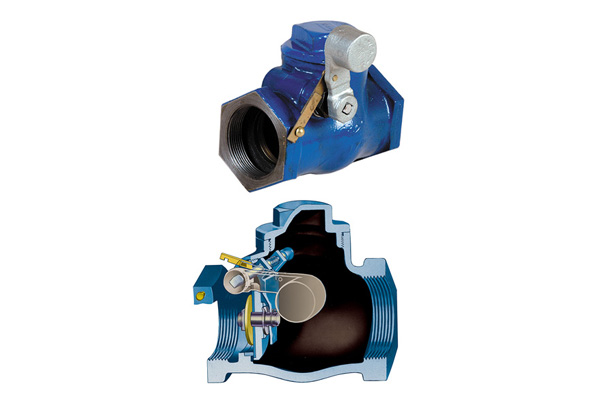

SWING CHECK VALVE

OP.AST.175

› Installed in-line on fuel supply piping, allows one-way

product flow

› The valve poppet opens with flow of product and closes

to prevent back-flow

› Rated at normal pressure limit of 8.6 bar and has a

body design to allow full flow rate

› Temprature limit is 107 degree celcius.

› Supplied with 2” and 3” with female NPT thread

connection