FRANKLIN

SENSORS

No matter what the monitoring application is, Franklin Fueling Systems offers a sensor solution tailored to the specific requirements of each application.

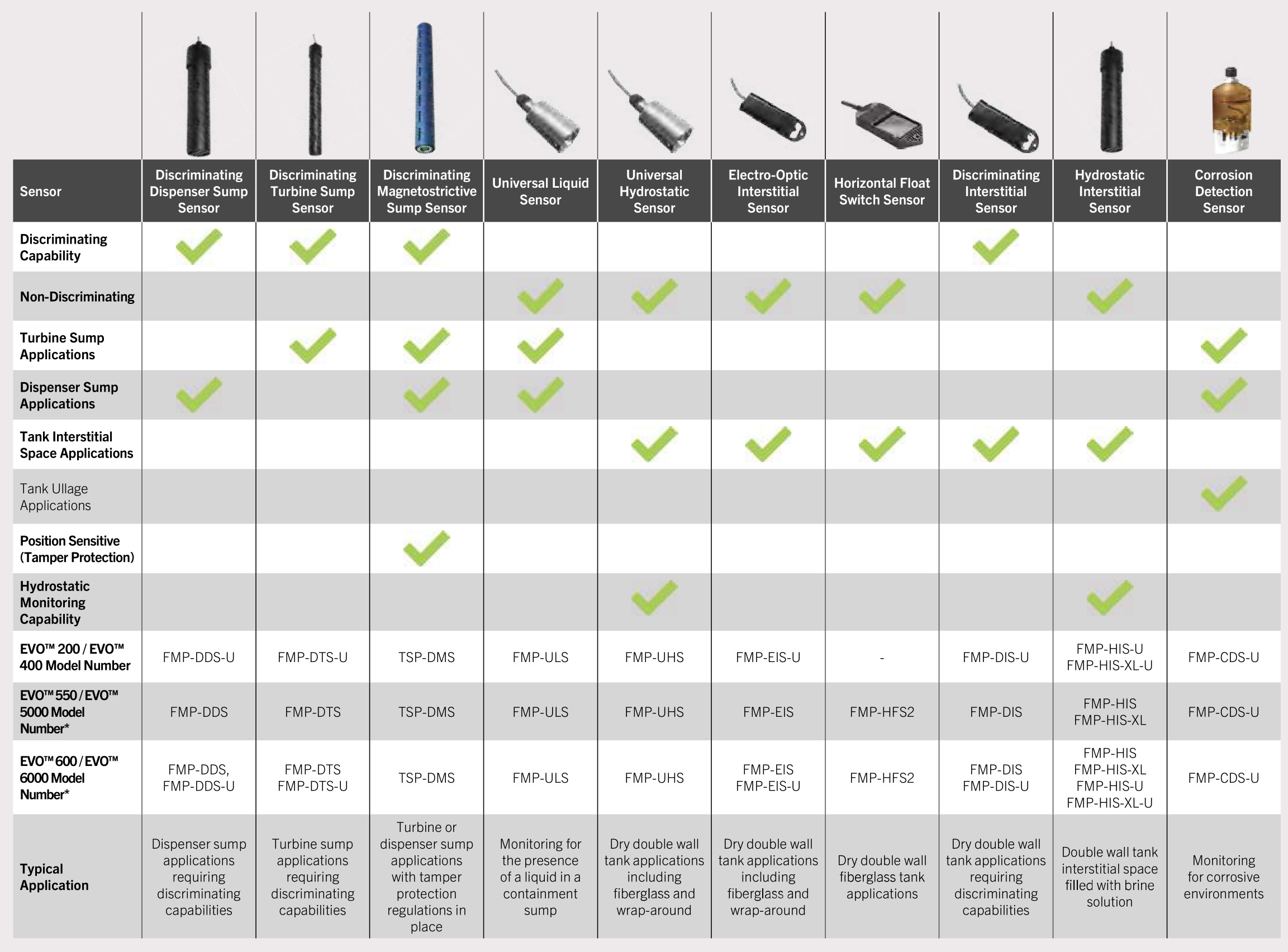

SENSOR SELECTION GUIDE

Does your application require the need to tell the difference between fuel and water?

Discriminating Sensors are able to detect and send an alarm signal if the presence of liquid is detected inside and can also differentiate between liquid and hydrocarbons.

Does your application only require the need detect any type of liquid?

Non-Discriminating Sensors are able to detect and send an alarm signal if the presence of liquid is detected inside of a containment space.

What type of Automatic Tank Gauge (ATG) are you connecting to?

Select the appropriate model number of sensor that's compatible with your ATG using the chart below.

DISCRIMINATING DISPENSER SUMP SENSOR (DDS)

The DDS is a discriminating dispenser sump sensor which provides reliable monitoring of dispenser pans and containment sumps.

HIGHLIGHTS

• Uses magnetic float switches to detect liquid at two levels.

• Innovative polymer strip detects hydrocarbons along sensor and floating on water.

• Compatible with common fuels and chemicals.

• Detects liquid at 11⁄2" (38 mm) from base.

• Detects hydrocarbons on sensor and floating on water.

Digitally encoded status information sent from microcomputer to ATG from 775+ feet (236 m).

Alarms to indicate liquid in sump, hydrocarbon detected, sump is full, and sensor malfunction.

Variety of mounting methods possible depending on location. Bracket provided for quick installation.

ORDERING INFORMATION

| Model | Description |

|---|---|

| FMP DDS | Discriminating dispenser sump sensor (EVOTM 550, EVOTM 5000, EVOTM 600 and EVOTM 6000) |

| FMP DDS-U | Discriminating dispenser sump sensor (EVOTM 200, EVOTM 400, EVOTM 600 and EVOTM 6000) |

| TSP-KS | UnistrutTM mounting kit |

Note: The FMP-DDS wires to the 3-wire sensor module and the FMP-DDS-U wires to the probe module.

DISCRIMINATING TURBINE SUMP SENSOR (DTS)

The DTS is a discriminating turbine sump sensor that detects the presence of liquid and hydrocarbons when installed in tank containment sumps.

HIGHLIGHTS

• Uses magnetic float switches to detect liquid at two levels.

Innovative polymer strip detects hydrocarbons along sensor and floating on water.

• Compatible with common fuels and chemicals.

• Detects liquid at 1/2" (38 mm) from base.

• Detects hydrocarbons on sensor and floating on water.

• Digitally encoded status information sent from microcomputer to ATG from 775+ feet (236 m).

SPECIFICATIONS

Applications

» For containment sump monitoring.

ORDERING INFORMATION

| Model | Description |

|---|---|

| FMT DTS | Discriminating turbine sump sensor (EVOTM 550, EVOTM 5000, EVOTM 600 and EVOTM 6000) |

| FMT DTS-U | Discriminating turbine sump sensor (EVOTM 200, EVOTM 400, EVOTM 600 and EVOTM 6000) |

| TSP-KS | UnistrutTM mounting kit |

Note: The FMP-DTS wires to the 3-wire sensor module and the FMP-DTS-U wires to the probe module.

DISCRIMINATING MAGNETOSTRICTIVE SENSOR (DMS)

The DMS sensor is a fast acting discriminating sensor that utilizes magnetostrictive technology to provide reliable monitoring of dispenser pans and containment sumps. Its floats can detect the presence of water or hydrocarbons and also ensure that the sensor installation has not been tampered with. The DMS sensor can report water warnings and programmable water alarm points as well as product alarms.

HIGHLIGHTS

• Utilizes proven magnetostrictive technology.

• Water warning, water alarm, and product alarm.

• Tamper protection feature will alarm if sensor is moved from installed position.

• Alarms and recovers quickly when hydrocarbons are present.

SPECIFICATIONS

Application

» For containment sump monitoring.

ORDERING INFORMATION

| Model | Description |

|---|---|

| TSP-DNS-12 | Discriminating magnetostrictive sensor, monitors 12" (305 mm) of liquid & measures 22" (559 mm) in length (all EVOTM Series ATGs) |

| TSP-DNS-24 | Discriminating magnetostrictive sensor, monitors 24" (610 mm) of liquid & measures 34" (864 mm) in length (all EVOTM Series ATG). |

| TSP-KS | Unistrut mounting kit |

Note: This sensor communicates with the ATG via the TS-PRB probe module.

UNIVERSAL LIQUID SENSOR (ULS)

Based on float-switch technology and made of chemically-resistant materials, the ULS is a low-cost sensor that can be installed in sumps, dispenser pans, steel double wall tanks or other locations where the presence of liquid indicates a leak has occurred.

HIGHLIGHTS

• Highly reliable float technology and closed output circuit ensures that leaks are detected.

• Chemical-resistant materials assure compatibility with most liquids.

• Each ULS sensor comes with a 25' (7.6 m) cable. 1/2" NPT thread is provided on the compression gland fitting attached to the sensor's cable, allowing it to be suspended from standard electrical boxes and fittings. The sensor may be positioned vertically by adjusting cable length. For steel interstitial tanks, ULS is lowered into the opening provided on the tank and is suspended by optional TSP-K12 installation kit. Other mounting methods available depending upon application and location.

SPECIFICATIONS

Applications

» For containment sump monitoring.

ORDERING INFORMATION

| Model | Description |

|---|---|

| FMP-ULS | Universal liquid sump sensor (all EVOTM Series ATGs) |

| TSP-ULS | Universal liquid sump sensor (for use with S940 only) |

| TSP-K12 | Interstitial sensor riser cap kit for 2" (51 mm) riser pipes |

Note: This sensor communicates to the ATG using 2 wires on the 2-wire sensor modules or the 3-wire sensor module. It cannot be wired to the probe module.

UNIVERSAL HYDROSTATIC SENSOR (UHS)

The UHS uses float switch technology to continuously monitor liquid- filled double wall containment sumps. Normally submerged, the single float UHS will provide an indication if there is a loss of monitoring liquid.

HIGHLIGHTS

• Highly reliable float technology and closed output circuit ensures that leaks are detected.

• Chemical-resistant materials.

• Each UHS sensor comes with a 25' (7.6 m) cable. The sensor can be installed into the reservoir of a liquid filled double wall containment sump. The sensor must be installed in a vertical position at a level where it is normally submerged. The UHS sensor will alert if the liquid level drops below the bottom of the sensor.

SPECIFICATIONS

Applications

» Typically used for hydrostatic monitoring of the liquid in a double wall sump interstice.

ORDERING INFORMATION

| Model | Descriptions |

|---|---|

| FMP-UHS | Universal hydrostatic sensor (all EVOTM Series ATGs) |

| TSP-ULS | Universal hydrostatic sensor (for use with S940 only) |

| HP-KIT | Hydrostatic monitoring installation kit. Includes: flexible brine tube, sensor housing clamp, sensor housing, sensor cap, and hardware |

Note: The FMP-UHS wires to the 2 wire sensor module or the 3 wire sensor module. It cannot be wired to the probe module.

ELECTRO-OPTIC INTERSTITIAL SENSOR (EIS)

Utilizing electro-optic technology, and made of chemically-resistant polysulfone plastic, the EIS may be installed in sumps, double wall tanks, or other locations where the presence of liquid indicates a leak has occurred.

HIGHLIGHTS

• Highly accurate electro-optic technology and closed output circuit ensures that leaks are detected.

• Chemical-resistant materials.

• Can be installed in fiberglass or steel double wall tanks.

• Utilizes light-emitting diodes and prisms to indicate if a leak has occurred.

• Each EIS comes with 25' (7.6 m) of oil-resistant cable. For fiberglass tanks, the EIS is pulled into the interstitial space using a "fish" string or wire. For steel interstitial tanks, the EIS is lowered directly to the bottom of the interstitial space through a 2" NPT fitting provided for that purpose on the tank. Optional installation kits are available which include a riser cap and other parts required to complete installation.

SPECIFICATIONS

Applications

» For dry tank interstitial monitoring.

ORDERING INFORMATION

| Model | Description |

|---|---|

| FMP-EIS | Electro-optic interstitial sensor (EVOTM 550, EVOTM 5000, EVOTM 600 & EVOTM 6000) |

| FMP-EIS-U | Electro-optic interstitial sensor (EVOTM 200, EVOTM 400, EVOTM 600 and EVOTM 6000) |

| TSP K12 | Interstitial sensor riser cap kit for 2" riser pipes |

Note: The FMP-EIS wires to the 3 wire sensor module and the FMP-EIS-U wires to the probe module.

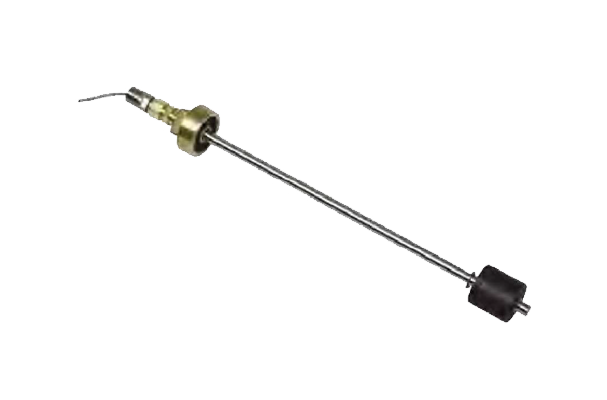

HORIZONTAL FLOAT SWITCH SENSOR (HFS)

The HFS is designed for liquid detection in dry fiberglass tank interstitial spaces. These 2-wire, non-discriminating liquid sensors are used with all EVOTM Series Automatic Tank Gauges (ATGs).

HIGHLIGHTS

• Fiberglass interstitial monitoring using a 2-wire sensor.

• For dry fiberglass tank interstitial monitoring.

• Highly reliable magnetic-float/reed-switch technology.

• Chemical-resistant materials.

• Easily fits tight interstitial spaces.

• Rounded design makes it easy to remove for cleaning and reinstall after an alarm condition has been triggered or for maintenance and testing.

• Each HFS comes with a 25' (7.6 m) oil-resistant cable. For fiberglass tanks, the sensor is pulled into the interstitial space using a "fish" string wire. Optional installation kits are available which include a riser cap and other parts required to complete the installation.

SPECIFICATIONS

Applications

» For dry tank interstitial monitoring.

ORDERING INFORMATION

| Model | Description |

|---|---|

| FMP HFS2 | Horizontal float switch sensor (all EVOTM Series ATGS) |

| TSP-K12 | Interstitial sensor riser cap kit for 2" riser pipes |

| TSP-KW4 | Interstitial sensor riser cap kit for 4" riser pipes |

Note: The FMP-HFS2 wires to the 2 wire sensor module or the 3 wire sensor module. It cannot be wired to the probe module.

DISCRIMINATING INTERSTITIAL SENSOR (DIS)

The DIS installs in the interstitial space of steel and fiberglass double wall tanks and sumps and detects the presence of various liquids in tanks as well as sumps and other locations.

HIGHLIGHTS

• Uses light beam traveling through probe to determine if sensor is wet.

• Microprocessor inside sensor interprets readings and communicates data to the EVOTM Series ATG.

• Fail-safe digital communications with built-in alarm if sensor malfunctions.

• Alarms indicate petroleum present, water present, and sensor malfunction.

• Each DIS comes with 25' (7.6 m) of oil-resistant cable. For fiberglass tanks, the DIS is pulled into the interstitial space using a "fish" string or wire. For steel interstitial tanks, the DIS is lowered directly to the bottom of the interstitial space through a 2" NPT fitting provided for that purpose on the tank. Optional installation kits are available which include a riser cap and other parts required to complete installation.

SPECIFICATIONS

Applications

» For dry tank interstitial monitoring.

ORDERING INFORMATION

| Model | Description |

|---|---|

| FMP DIS | Discriminating interstitial sensor (EVOTM 550, EVOTM 5000 EVOTM 600 and EVOTM 6000) |

| FMP-DIS-U | Discriminating interstitial sensor (EVOTM 200, EVOTM 400, EVOTM 600 and EVOTM 6000) |

| TSP-KI2 | Interstitial sensor riser cap kit for 2" riser pipes |

HYDROSTATIC INTERSTITIAL SENSOR (HIS)

The HIS detects leaks in double wall tanks where the interstitial space is filled with a liquid brine solution. The polyester, Nitrile, and epoxy construction is compatible with all types of brine.

HIGHLIGHTS

• Versatile sensor for virtually all fiberglass double wall tanks equipped for hydrostatic leak detection.

• Microcomputer monitors liquid at varying levels within tanks and relays digitally encoded status information via the fail-safe sensor digital communication system to fuel management system or Tank Sentinel® ATGS, alerting of any alarm conditions.

• For installation, lower the HIS to the bottom of the brine reservoir of double wall tank. The normal brine level should reside half way up the sensor. Sensors include the TSP-KV4 vented 4" riser cap.

SPECIFICATIONS

Applications

» For liquid-filled tank interstitial monitoring.

ORDERING INFORMATION

| Model | Description |

|---|---|

| FMP HIS | Hydrostatic interstitial sensor, 11"* (EVOTM 550, EVOTM 5000, EVOTM 600 and EVOTM 6000) |

| FMP HIS XL | Hydrostatic interstitial sensor, 21"* (EVOTM 550, EVOTM 5000, EVOTM 600 and EVOTM 6000) |

| FTP-HIS-U | Hydrostatic interstitial sensor, 11" (EVOTM 200, EVOTM 400, EVOTM 600 and EVOTM 6000) |

| PMP-HIS-XL-U | Hydrostatic interstitial sensor, 21" (EVOTM 200, EVOTM 400, EVOTM 600 and EVOTM 6000) |

| TSP-KV4' | Hydrostatic sensor vented riser pipe cap kit for 4" riser pipes |

Note: The FMP-HIS/FMP-HIS-XL wire to the 3 wire sensor module, and the FMP-HIS-U/FMP-HIS-XL-U wire to the probe module. *One TSP-KV4 is already included with each HIS or HIS-XL sensor.

HIGH PRODUCT LEVEL SENSOR (HLS)

The HLS level sensor is an overfill prevention switch that may be adjusted to operate over a wide range of levels. The HLS is based on float-switch technology and is made of chemical- resistant materials to assure compatibility with most liquids.

HIGHLIGHTS

• Each sensor is supplied with jacketed cable five feet in length.

• The normally-closed output circuit provides supervised operation, ensuring that broken wires and similar failures will not go undetected.

• A small magnetically-activated read switch is located inside the body of the sensor. Tiny magnets are positioned inside a lightweight float which is free to move up and down along the shaft so that the magnets are below the read switch. When the sensor is immersed in liquid, the float rises and the magnet activates the read switch, signaling the ATG that the high limit has been reached.

SPECIFICATIONS

Applications

» Overfill protection switch.

ORDERING INFORMATION

| Model | Description |

|---|---|

| TSP-HLS-15 | High product level sensor, 15" long, installed in tank (EVOTM 550, EVOTM 5000, EVOTM 600, EVOTM 6000 ATGs) |

| TSP-HLS-15/SS | High product level sensor, stainless steel 15" long, installed in tanks containing alternative fuels (EVOTM 550, EVOTM 5000, EVOTM 600, EVOTM 6000 ATGs) |

| TSP HLS 30 | High product level sensor, 30" long, installed in tank (EVOTM 550, EVOTM 5000, EVOTM 600, EVOTM 6000 ATGS) |

| TSP HLS 30/SS | High product level sensor, stainless steel 30" long, installed in tanks containing alternative fuels (EVOTM 550, EVOTM 5000, EVOTM 600, EVOTM 6000 ATGs) |

Note: The TSP-HLS connects to the 2 wire sensor module or the 3 wire sensor module. It cannot be wired to the probe module.

CORROSION CONTROLTM CORROSION DETECTION SENSOR (CDS)

As part of the Corrosion ControlTM System the Corrosion Detection Sensor (CDS) provides automated notification of a corrosive environment in the tank ullage space. Keep the fuel system running at peak performance and avoid costly maintenance, equipment replacement, downtime, and system failure caused by excessive corrosion.

HIGHLIGHTS

• Sensor will detect the presence of corrosion on a sacrificial sample and provide an alarm.

• Protects the tank ullage from the formation of corrosion which can lead to fuel system deterioration.

• Displays a level reading for corrosion index via the EVOTM Series Automatic Tank Gauge (ATG) with programmable alarm types including:

• Corrosive Environment Present

• Corrosion Sensor Sample Error

• Corrosion Sample Needs Replacement

• Compatible with all blends of gasoline, diesel, and Ethanol.

• ATG compatibility:

• EVOTM 200 and EVOTM 400

• EVOTM 550 and EVOTM 5000

• EVOTM 600 and EVOTM 6000

SPECIFICATIONS

Applications

» Monitoring for a corrosive environment within a tank ullage space.

Theory of Operation

The CDS is installed in the tank ullage space. The intrinsically safe sensor utilizes an included quick disconnect cable to wire to any EVOTM Series ATG via the probe module (EVOTM 550, EVOTM 5000, EVOTM 600, EVOTM 6000) or any Intrinsically Safe (IS) channel (EVOTM 200 and EVOTM 400). The sensor utilizes a sacrificial metal screen which is used to detect the formation of corrosion. This screen can be removed and replaced upon the formation of corrosion.

ORDERING INFORMATION

Corrosion ControlTM Corrosion Detection Sensor

| Model | Description |

|---|---|

| FMP-CDS-U | Corrosion Detection Sensor (all EVOTM Series ATGs) |

| FMSP-RDS1 | Replacement detection screen, qty 1 |

| FMSP-RDS1O | Replacement detection screen, qty 10 |

| TSP-KS | UnistrutR mounting kit |

Note: this sensor communicates with the ATG via a TS-PRB probe module (EVOTM 550, EVOTM 5000, EVOTM 600, and EVOTM 6000) or via an IS channel (EVOTM 200 & EVOTM 400).